© Solvis GmbH

© Solvis GmbH

PVT collectors combined with heat pumps

Generating Electricity and Heat More Efficiently with Solar Energy

Photovoltaic thermal systems can generate electricity and heat with solar energy. Funded by the Federal Ministry for Economic Affairs and Climate Action, researchers have optimised this system in three ways: they developed new collector concepts, efficient production and optimised operation in combination with heat pumps.

Urban areas are usually densely populated sand have a high energy demand. If this demand is to be met with renewable energy, suitable areas must be used as efficiently as possible to generate electricity and heat. So-called photovoltaic-thermal (PVT) collectors, which function as a hybrid, are ideal for this purpose: They convert solar energy into both electricity and heat. This in turn can be used as driving energy or heat source for heat pumps. This can be particularly relevant for older buildings in densely built-up areas that are in need of renovation, where it is difficult to tap the heat sources of geothermal energy or outside air.

In the PVTsolutions research project, a team from the Fraunhofer Institute for Solar Energy Systems ISE, together with the heating system provider Solvis and the solar absorber manufacturer Solab, has currently developed PVT collectors that can achieve good profit in combination with a heat pump as well. The researchers were able to successfully register one of their developments with the European Patent Office. The Federal Ministry for Economic Affairs and Climate Action has funded the PVTsolutions project with around 1.8 million euros.

Two PVT collectors for different temperature levels

On a pilot production line, the project partners produced two different types of PVT collectors, which were tested in demonstration buildings as well.

PVT collector with front glass and insulation

This is an insulated and front-covered collector. The additional front cover of the PV module with a glass pane and the thermal insulation on the back serve to minimise heat loss to the environment. This ensures that the highest possible inlet flow temperatures can be achieved with good efficiency. In a heating system with low-temperature hot water preparation, the PVT collector enables the direct use of heat without a temperature lift by a heat pump. The scientific team was able to show that direct storage tank charging (without a heat pump), especially in summer and in the transitional periods, is possible with good collector efficiency. By combining this function with a heat pump, the annual PVT collector profits can increase significantly.

PVT low-temperature collector

This uncovered collector variant is partially equipped with an air heat exchanger which is attached to the back of the absorber in form of aluminium fins. In this way, it is possible to provide source heat for a heat pump even without solar radiation. Experiments on small-scale absorber samples have shown that the lamellar structure enables an increase in performance of 50 percent and more compared to the sample without lamellae. In a real PVT installation, the increase is very much dependent on the installation situation. This type of collector is specifically designed to function as a heat source for a heat pump in the heating system of a building.

Uncovered PVT collectors as the sole heat source for a heat pump

With this combination, the heat output and the system performance and efficiency depend essentially on the size of the transfer surface to the ambient air or the PVT collector field: The larger the transfer surface or PVT collector surface increased by fins, the higher the evaporator temperatures of the heat pump and the better its annual performance factor (COP). However, a more complex design or a larger collector area also require higher investment costs.

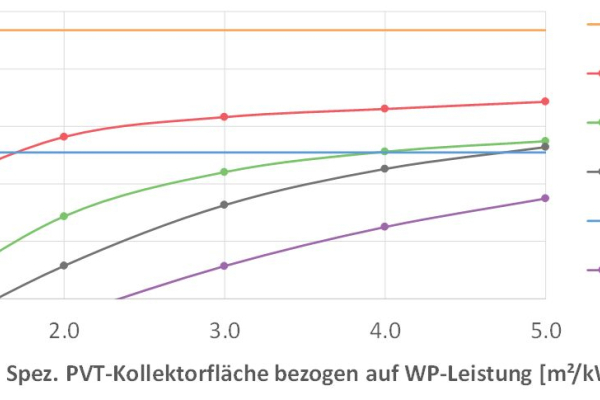

In order to identify and compare the optimum system efficiency and heat production costs for different PVT collector types, system simulations were carried out varying the PVT collector types and the installed collector area. The plotting of the annual performance factor or the heat production costs over the collector area used per nominal heat output of the heat pump shows the optimal or required minimum areas (Fig. 2). It was shown, for example, that a collector area larger than four square metres is required for a PVT collector without insulation on the back in order to achieve values for the coefficient of performance comparable to those of an air-source heat pump.

In general, the better the thermal connection of the fluid to the environment, the higher the heat output and thus the higher the COP. This can be achieved, for example, by an optimised heat exchanger in the PVT collector. If the collector field is sufficiently large, an annual performance factor between that of air and brine heat pumps can be achieved. Depending on the collector design, approximately three to five square metres of collector field are required per kWth of nominal heat output of the heat pump.

Heat pump booster with covered PVT collectors

Especially in apartment buildings, there is a high demand for hot water. Direct use of PVT heat is often not possible with low solar radiation due to the high temperatures required for hot water. Therefore, researchers investigated how covered PVT collectors can best be integrated in those buildings. For this reason, they combined the system with a heat storage tank in which a so-called booster heat pump heats the upper storage volume while cooling the lower storage volume. Due to the low storage temperatures in the lower volume, the PVT collectors operate at a low temperature level and thus achieve high thermal and electrical yields.

It was found that the use of a booster heat pump increases the thermal output of PVT collectors (up to 300 percent with covered PVT collectors). Since the source temperature is raised to the set temperature by the heat pump even with low irradiation, a significantly larger share of renewable heat can be used for hot water preparation. The contribution of the fossil-fuel boiler in the example simulation can therefore be reduced by 33 percent.

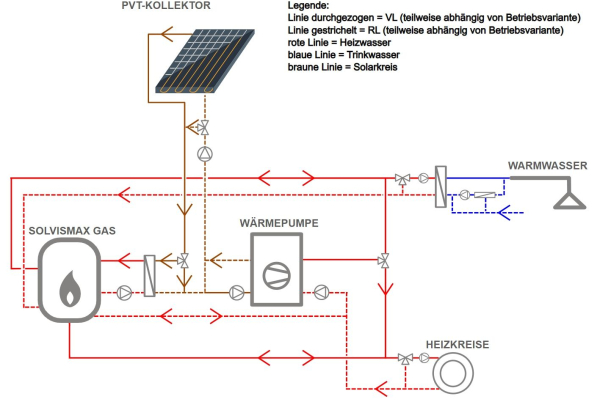

Practical tests in an apartment building and an office building

The experts tested the developed PVT collectors and the different system configurations in an apartment building in Salzgitter-Hallendorf in Lower Saxony (Fig.1 and 4) and an office building in Wierthe, near Braunschweig. For this purpose, they equipped the systems with measurement technology, recorded their operation for several months and evaluated the collected data. In the apartment building, ten covered PVT collectors (17 m2), one 950-litre heating water storage tank with integrated heating module (gas condensing boiler), one hot water and solar station as well as one booster heat pump were used (Fig.3). By continuously recording the operating data, the system could be improved gradually. The evaluation of the results of the demonstration system is being continued both by Solvis and in the integraTE project.

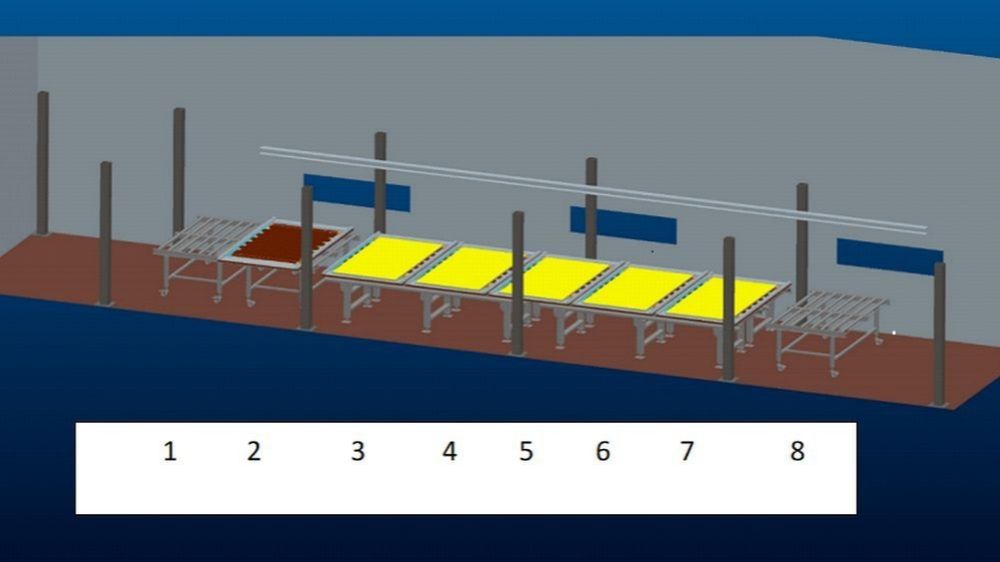

In Wierthe, 20 uncovered PVT collectors on a wall-hanging substructure (Fig. 5) with a total gross area of 33.5 square metres and 6.6 kWp of electrical power were used in five sub-arrays connected in parallel (Fig. 6) which directly supplied the source side of a heat pump with a nominal output of 8 kW. The heat pump covers a partial load of a larger office building, which has the usual energy standard for older buildings.

Results of operating the demonstration system with uncovered PVT collectors

- Contrary to expectations, increasing the surface area of the back of the PVT collectors with aluminium laminates did not produce any measurable advantage under real conditions in this installation situation.

- The heat pump of the demonstration system ran even under unfavourable conditions. The use of the integrated heating rod was not necessary.

- Even with a reduced area ratio (2.5 m2/kW), it was possible to provide temperatures for domestic hot water preparation and radiator heating in the existing building.

- When irradiated, the PVT collectors provided source temperatures that were in part significantly higher than the outside air temperatures.

- Very good coefficients of performance were achieved, ranging from 3.2 to over 4 in the individual monthly averages.

Bonding, Joining, Finishing: The path to an optimised PVT collector

In the PVTsolutions project, the researchers additionally developed a manufacturing technique that enables the optimised production of covered and uncovered PVT collectors. At first, it was necessary to adapt the absorber component. The challenges here were the choice of materials and joining technology. For example, adhesives in PVT collectors must be able to withstand seasonally fluctuating temperatures as well as snow and wind loads, while retaining their strength and elasticity as far as possible. The experts carried out various tests until they finally found the optimal combination of adhesive and bonding method for the production conditions.

The researchers identified aluminium expanded metal as an alternative to previously used absorber plates. Those can compensate for a large part of the length changes that occur in practice, which also affect the bonded joints. These stresses occur in practice because the thermal expansion coefficients of aluminium and glass differ. A patent application at the European Patent Office for the stress-free, two-dimensional bonding of an absorber by means of an expanded metal mesh was successful and published at the end of 2022. For production, the experts decided on a line process in only one direction (see in the infobox). In a line process, a maximum of one drive and the control of the "returning line" are required.

Market launch planned from 2023

The PVT developments and the experience with the pilot production line have created good conditions for a rational and more cost-effective series production of the PVT collectors. A brand launch of the uncovered PVT collectors is planned for 2023 and the distribution of a PVT complete system from 2024.