Für eine erhöhte Belastbarkeit und Präzision von Clamp-On-Messungen entwickeln die Forscher in diesem Projekt Korrekturalgorithmen für Clamp-On-Durchfluss- und Clamp-On-Temperaturmessungen. Die Ultraschall-Durchfluss-Messtechnik kann auch bei ungünstigen Einbaubedingungen - z. B. hinter Rohrbögen - durch die Korrekturalgorithmen belastbare Ergebnisse von hoher Präzision liefern. Das Messsystem wird für die unterbrechungsfreie Betriebsanalyse und -optimierung von Wärmeübertragern und Wärmeübertragernetzwerken entwickelt. Durch Kombination der Messdaten mit hochauflösenden thermohydraulischen Modellen der Wärmeübertrager können weitreichende Betriebsoptimierungsanalysen durchgeführt werden.

Heat exchangers essentially determine the energy efficiency and thus the operating costs of technical systems (costs for fuel, costs for pump operation, maintenance costs, production losses). The operation strategy for heat exchangers has a decisive influence on product quality and operational safety. The research project “nivEx” is concerned with optimising the operation and design of heat exchangers based on reliable operating data. For this purpose, a mobile measurement and analysis system is being developed that records plant operation data without interupting the plant operation for the installation of the measurement devices. New methodical means allow for higher precision and reliability of ultrasonic clamp-on flow measurements than commercially available systems.

Today, heat exchangers are designed on the basis of just a few stationary and theoretically specified operating parameters. However, the actual operating conditions often differ significantly from these assumptions. For example process dynamics, alternating media composition or changes in material and surface properties (eg. fouling or corrosion) as well as the long-term behaviour are not necessarily taken into account within the equipment design. A lack of knowledge about energy-efficient operation, the use and integration of existing energy sources (via pinch analysis) as well as the necessary maintenance measures also result that heat exchangers are not adapted sufficiently to the actual process in the design phase.

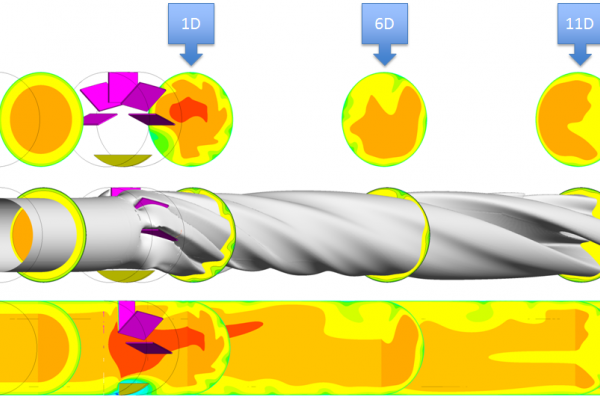

Although non-invasive flow measurement and temperature measurement techniques are available on the market, they are subject to various types of disturbances under practical conditions, which are not compensated in commercially available systems. Ultrasonic flow measurements are for example adversely affected by pipe elbows, valves or media inhomogeneties, which can lead to high measurement deviations. Surface temperature sensors must be sufficiently isolated from the environment and thermal inertia must be considered to infer the actual media temperature from the indicated sensor temperature.

Research focus

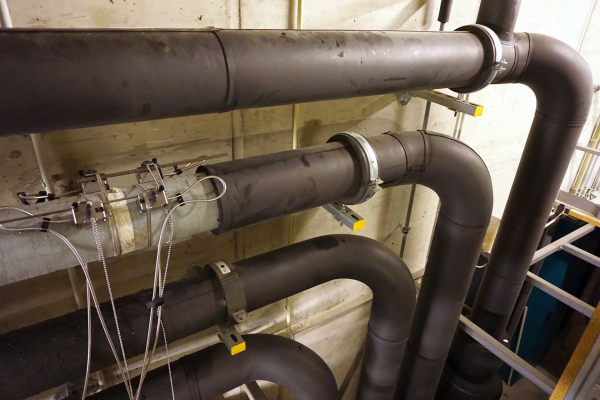

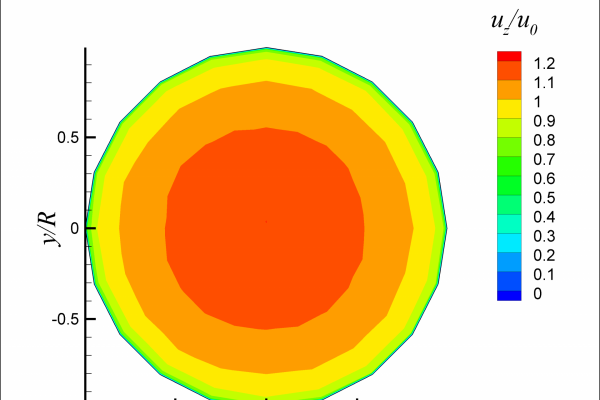

Commercially available ultrasonic clamp-on flow measurement technology and commercially available clamp-on temperature sensors are being used as basis of the measurement and analysis system. For rotationally symmetrical flow profiles, commercially available ultrasonic flow measurement technology can achieve good measurement accuracies for a wide range of media, pipe materials, pipe geometries and process conditions. However, the piping system around heat exchangers often contains disturbances such as pipe elbows and double bends that adversely affect the accuracy of the measurements, since flow profile symmetry is disturbed. In this project, a clamp-on system for measuring the temperature and flow rate is being developed that meets high accuracy requirements even under disturbed flow conditions. The system is metrologically validated by the national metrological institute of Germany, Physikalisch Technische Bundesanstalt (PTB).

At first, the Institute for Mechanical and Systems Engineering at TU Berlin and the PTB are developing correction algorithms for clamp-on flow measurements and clamp-on temperature measurements that compensate for the measurement inaccuracies caused by disturbances. Secondly, the ADAKOM GmbH develops heat exchanger operation analysis tools, which are fed with the previously corrected measurement data. The development will be concluded by field tests scheduled for 2018 in order to prove technical and economical feasibility. Industry partners are the Karlsruhe Institute of Technology, ADM WILD Europe GmbH & Co. KG, MAN Diesel & Turbo SE, Vivantes, Kühner Wärmetauscher and Brandenburgische Liegenschaftsbetriebe (BLB). Thus, the new measurement and analysis system is tested in various industries such as building services, food industry and large-scale process industry.

Successes

Successful optimization analyses for cooling plants, ice storage systems, compressed air coolers and pasteurisation plants have already been carried out.

Application

The developed measurement and analysis system identifies faulty operating modes and/or configurations of heat exchangers and generates case-specific optimisation recommendations. Optimization recommendations could be for example:

- Cost minimization related to pressure losses, cooling/heating costs or maintenance costsReconditioning of the heat exchanger

- Redesign of the heat exchanger

- Operational forecasts (“what if” - scenarios)

- Pinch analysis (energy integration in heat exchanger networks)

- Fouling monitoring and forecasting Optimization of product thermal stress

- Reduction of downtimes and secondary processes (e.g. cleaning cycles)

- Hydraulic balancing.