© Projektträger Jülich / Forschungszentrum Jülich GmbH

© Projektträger Jülich / Forschungszentrum Jülich GmbH

Sustainable materials in focus

How innovative insulation materials make buildings more energy efficient

Thermal insulation is a central building block of the energy transition. Insulation materials made from sustainable materials do not only improve the energy efficiency of buildings, they also offer ecological advantages due to lower CO2 emissions during their production and recycling.

The energy transition requires not only the expansion of renewable energies, but also a reduction in overall energy consumption. One important lever here is the insulation of buildings: efficient insulation can significantly reduce heating and cooling requirements, which not only relieves the burden on the environment but also lowers energy costs. In this context, sustainable insulation materials in particular are becoming increasingly important because they offer ecological advantages and conserve resources.

The Heat Transition Mission of the 8th Energy Research Programme of the Federal Ministry for Economic Affairs and Climate Protection (BMWK) also addresses the topic of insulation. One sprinter goal of the mission is to develop and use new types of building insulation materials by 2030. These should only require half the primary energy input over their entire product life cycle compared to today's conventional insulation materials. The innovative materials should provide the same level of insulation as conventional products.

Three BMWK-funded research projects dealing with the development and application of such materials are OrganoPor_Fassade, BioFassade and HydroPhiber. In collaboration with partners from the construction industry, scientists are researching and developing sustainable insulation materials.

OrganoPor_Fassade: Sustainable insulation made from biodegradable materials

The OrganoPor_Fassade research project, coordinated by the Fraunhofer Institute for Structural Durability and System Reliability LBF, is focusing on biodegradable materials for insulating buildings. The aim is to develop a porous insulation material based on renewable raw materials. These materials not only have good insulating properties, but also can be disposed of in an environmentally friendly way or recycled at the end of their service lifetime. OrganoPor_Fassade could thus make a significant contribution to reducing construction waste and promoting a circular economy.

‘Our goal is to replace polystyrene foam panels,’ explains project manager Dr Roland Klein from the Fraunhofer LBF. ’It is important to us not to use materials that have to be specially cultivated, but instead to use residual and side streams from agriculture and forestry.’ In concrete terms, rape straw is used in OrganoPor_Fassade, which is then glued with a lignin-based binder and compressed under heat. The panels developed in the project already achieve similarly high insulation values as standard soft wood fibre panels, while being less flammable.

More information about the OrganoPor_Fassade project can be found here.

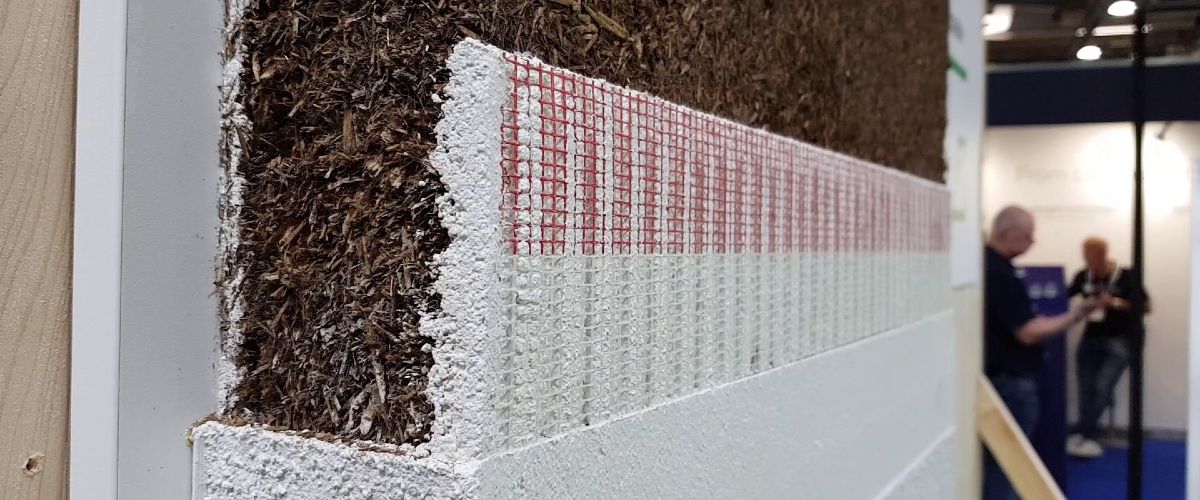

BioFassade: Facade elements with thermal insulation made of biopolymers

The BioFassade project, coordinated by the Karlsruhe Institute of Technology (KIT), is dedicated to the development of a facade system in which insulating panels made of biopolymers are used. The focus is on the use of biogenic residues such as wood fibres and straw, which not only offer a sustainable alternative to conventional insulation materials but are also compostable. The cellulose acetate fibres used are currently utilised primarily in the production of cigarette filters.

But it is not only the insulating material itself that offers ecological advantages, the facade system does too: ‘The entire facade system is designed to be easy to assemble and just as easy to dismantle,’ explains Prof. Dr. Rosemarie Wagner from the KIT. ‘We don't want any dowels or adhesives; we want to develop a system that is only screwed together.’ Metal profiles and special brackets are used for this purpose, which hold the insulating material to the wall and at the same time ensure good air circulation. In addition, the researchers want to replace the weather layer and various corner and edge profiles, which currently mostly consist of PVC, with elements made of biopolymers.

More about the BioFassade project can be found here.

HydroPhiber: Renewable building and construction materials for the circular economy

The HydroPhiber project also aims to develop highly insulating building and construction materials from renewable raw materials. These should manage without petroleum-based products, while still offering mechanical stability, low conductivity and resistance to environmental influences. The researchers are focusing on fast-growing plants such as special reed species (Miscanthus x giganteus), deciduous trees (Paulownia ssp.) and residual materials such as spruce. These sustainable materials absorb CO2 during their growth phase and thus contribute to climate protection even before they are used in buildings. Environmentally harmful products are also avoided during processing. The researchers want to develop compostable products and thus enable cradle-to-cradle recycling.

More about the HydroPhiber project can be found here.

Innovative insulation materials offer a forward-looking solution

The three projects make it clear that sustainable insulation materials have enormous potential for improving the energy efficiency of buildings and thus making an important contribution to the energy transition. By combining high performance with environmental protection in production and recycling, they offer a forward-looking solution for the construction industry.