©SWN

©SWN

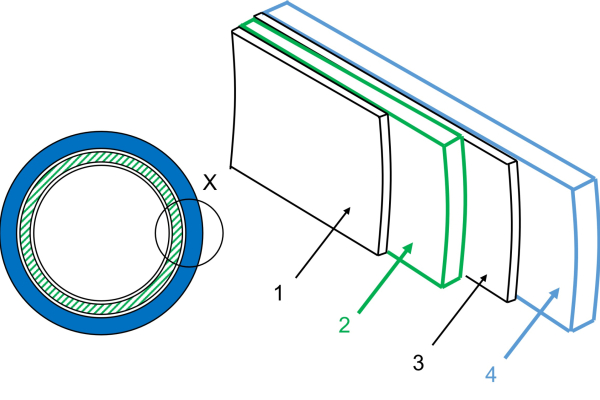

Hose Liner Inserted into Pipe System

Rehabilitation of District Heating Pipes Simplified

Households are to be increasingly supplied with green district heating in the future, according to the Federal Ministry of Economics. For this to be possible in the long term, heat pipelines must be maintained. A team in the FW-Liner project has investigated how these can be renovated in a way that conserves resources.

District heating networks in Germany have been increasingly installed since the 1950s and are now reaching the end of their planned useful life. At the same time, replacing the pipelines is very costly: Masses of soil have to be excavated and the surfaces subsequently restored, road and delivery traffic is disrupted, and residents are inconvenienced by construction noise and dust.

In the "FW-Liner" project funded by the German Federal Ministry of Economics and Climate Protection, experts led by "AGFW - Der Effizienzverband für Wärme, Kälte und KWK" have now developed a more efficient and environmentally friendly solution. To do this, they are using a process that is already used in pressureless wastewater networks and drinking water pressure networks: so-called hose liners, which are impregnated with resin and made of glass fiber-reinforced plastic (GRP), are inserted into the pipe system and harden on site. One manufacturer of these liners, SAERTEX multiCom GmbH, is part of the FW-Liner research consortium.

Special challenges in district heating pipelines

District heating pipelines are subject to higher temperatures and different pressure conditions than wastewater and drinking water networks. "We have adapted the hose liners previously used there to the thermal, mechanical and chemical stresses in district heating pipelines," explains project manager Sebastian Grimm from AGFW. "In doing so, we focused on the hot water district heating systems most commonly used in Germany."

Temperature load changes in particular stress district heating pipelines. As more volatile renewable energy is fed into the grids in the future, and sector coupling and the associated changes in the electricity and heating markets increase, the experts expect these stresses to increase. Older district heating systems in particular are not designed for this.

Of the typical damage to district heating pipes, only those where the internal carrier pipe itself is affected can be repaired with a liner. These include defective weld seams, which can lead to leaks, or corrosion damage. "If a FW liner is used, maintenance measures can also be carried out selectively so that only individual network sections are affected. This reduces costs and means that the supply can be restored more quickly," says Grimm.

Materials suitable for district heating sought

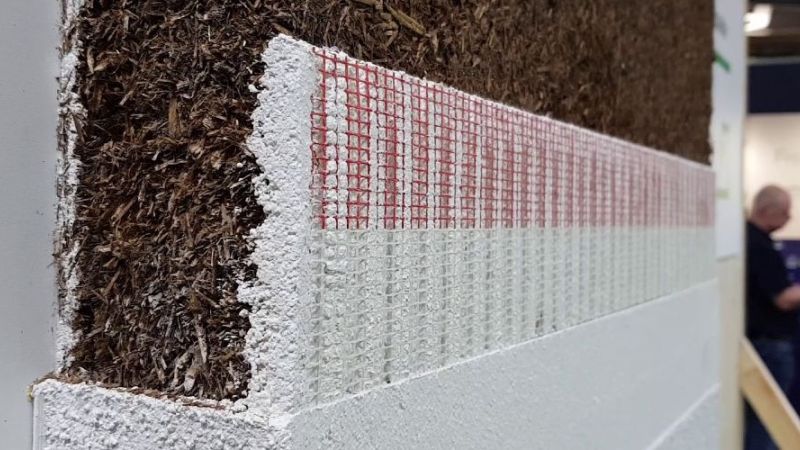

Resin, glass fiber scrim and protective film: These components of the hose liner in particular had to be optimized for the high loads in district heating networks. This means that the overall system must remain sufficiently leakproof and load-bearing at temperatures of up to 130 degrees Celsius. In addition, the experts had to ensure that medium- and long-term material changes would not have a detrimental effect on the heating medium.

"One of the biggest challenges at the beginning of the research project was to find a resin that could withstand the high material stresses in district heating networks," says Grimm. The glass fibers are processed in a "scrim" which is impregnated with the resin. The combination of the glass fiber and resin components forms the glass fiber reinforced plastic (GFRP). The inner film serves as a further sealing element before, during and, if required, after the resin has cured. Only when the resin cures has the flexible tube become a stable tube.

After various investigations, the experts identified an industrial resin that is available on an industrial scale and can be used in liner production. A dissertation on the subject resulting from the project was awarded the "AVK Innovation Prize". Finally, the researchers in the project succeeded in developing the basic elements of a GRP pressure hose liner suitable for district heating (resin, glass fiber scrim and protective film). They were able to successfully test the resulting prototype in the laboratory.

FW liner installed in test line

Together with the municipal utilities and the city of Neumünster, the project partners also built a test line (see info box) in parallel operation with a real district heating network. There, a first prototype of the FW liner could be tested in practical operation and under construction site conditions, and concrete development needs could be derived.

After completion of the project, AGFW and local partners additionally tested another newly developed inliner rehabilitation method, which is installed in the test section. The practical experience gained from FW-Liner as well as the tests and investigations currently being carried out make it possible to assess the suitability of the new rehabilitation methods for district heating pipelines. This can provide initial guidance to interested district heating utilities. In addition, the findings will flow into the follow-up project SaniFern, which is also being funded by the BMWK.

Next challenge: side outlets in the district heating network

To increase the practical benefit, it makes sense that the hose liner can be used under as many FW-typical conditions as possible. One example is so-called side outlets. "These are required in district heating networks wherever lines branch off from the transport or distribution lines. Such side outlets are usually designed as T-branches," explains Grimm. In the follow-up project SaniFern, the project partners are now developing solutions to take side branches into account with the least possible effort when rehabilitating with FW liners. The aim is for this to also be possible without trenching. The experts are also compiling information on planning, construction and financing of the new rehabilitation method.