© GKM AG

© GKM AG

Launch of the Living Lab of the Energy Transition GWP

New: Large-Scale Heat Pumps in Germany’s District Heating Networks

A large proportion of Germany’s CO2 emissions can be attributed to the supply of heat. Large-scale heat pumps powered by greenhouse gas-free electricity could help the country to reduce its CO2 emissions. In the living lab of the energy transition focused on the installation, operation, monitoring, and system integration of large-scale heat pumps (LHPs) in district heating networks, these systems will now be connected to district heating networks at various types of location.

At five locations across Germany, numerous project partners (see right-hand side under “Contact”) will integrate LHPs into existing district heating systems over the next few years under the coordination of AGFW-Projekt GmbH. In addition to technical findings, they aim to discover – in cooperation with research institutions – how regulatory and economic frameworks can be adapted to establish LHPs on the district heating market. Moreover, the teams will conduct on-site investigations into the efficient integration of LHPs using operating concepts that are to be optimized. The aim is to make a sustainable, economically effective contribution to decarbonizing the supply of heat in Germany.

Bringing innovative technologies into application

GWP is a so-called Real Laboratory of the Energy Transition. In general, innovative technologies are tested in practical application under real conditions and on an industrial scale in this format funded by the Federal Ministry for Economic Affairs and Climate Action. Experts can then use the experience gained in the projects to decisively advance the far-reaching transformation of the energy system in Germany towards climate neutrality.

Challenge: Optimal integration of large-scale heat pumps into the German energy system

At present, LHPs in Germany are not economically viable without funding. This is due to the current statutory framework, specifically the high fees and levies that consumers have to pay for electricity. Furthermore, there is a lack of clear instruction and experience with regard to how LHPs could be optimally integrated into the German energy system. The living lab on LHPs is working to find solutions to this problem.

The project partners will set up LHPs at power plant sites in Berlin, Stuttgart, Mannheim, and Rosenheim. Partners at these sites are planning to install the LHPs close to existing heat generator locations. To ensure that connection costs are kept to a minimum for the new technologies, sufficient heat source capacities (e.g. from river water or low-temperature waste heat) will be available at each location.

In contrast with decentralized heat pumps, LHPs are able to utilize large, natural sources of heat and industrial waste heat sources with high energy potential at a low temperature level. LHPs are not often situated in direct proximity to heat consumers or cannot be accessed by individual consumers due to their size. They enable an efficient, electricity-based heat supply, particularly in areas with a high, specific heating demand that can be or are already being supplied with district heating.

Results can be transferred to other locations

Significant differences between the sites of the LHP living lab of energy transition can be found in the output (1.12–22 MW) of the heat pumps being integrated and in the type of heat sources. Other criteria include the existing heat generator structure to be extended and the situation in the power grid. Whether the grid is located in northern or southern Germany has an enormous influence on the operation of the heat pumps, whose operating parameters are adapted according to the requirements of regional heating networks. This permits a better understanding of the influencing factors. In addition, heat consumers vary from residential customers to industrial heat consumers. The variety between the locations means that it will be possible to apply results to other areas in Germany.

The district heating suppliers involved in the project will plan and install the LHPs before putting them into operation. They will then analyse and optimize their operation in cooperation with the scientific project partners over an extended period of time.

Profile of the five locations

Berlin-Neukölln power plant site

Seven large-scale boilers and seven combined heat and power (CHP) units are situated at the heating plant site. The fuels used are natural gas, wood pellets, hard coal, biomethane, and heating oil. Alongside the planned CHP charge air cooling system, further potential heat sources (e.g. river water heat and geothermal energy) are available for the LHPs to be installed at the site.

- Generation fleet before project start: 7 large-scale boilers and 8 power CHP units.

- Electrical output before project start: 11.4 MW

- Thermal capacity before project start: 192 MW

- Energy sources used before project start: natural gas, hard coal, wood pellets, biomethane and heating oil

- Planned thermal output of the large-scale heat pump: 1.3 MW

- Heat source: CHP unit charge air cooling

- Special features: 300 MWh heat storage and 10 MW power-to-heat plant

© Fernheizwerk Neukölln AG

© Fernheizwerk Neukölln AG

Stuttgart power plant site

At this site, district heat is produced by means of combined heat and power; it also features a waste incineration plant. Its electrical output amounts to 184 MW and its thermal output is 447 MW. Three waste-fired boilers and three coal-fired boilers supply the common steam range, one counter-pressure and two extraction condensing steam turbines, and several hydraulically separated district heating networks. The large-scale heat pump is expected to have a total output of more than 20 MWth. It will be powered by “green electricity” produced on site through thermal waste recycling.

- Generation fleet before project start: 3 waste boilers, 3 coal boilers

- Electrical output before project start: 183 MW

- Thermal capacity before project start: 450 MW

- Planned thermal capacity of the large-scale heat pump: 23 MW

- Heat source: Cooling water

- Special features: Location with very tight space conditions while maintaining the supply capacity.

© EnBW AG

© EnBW AG

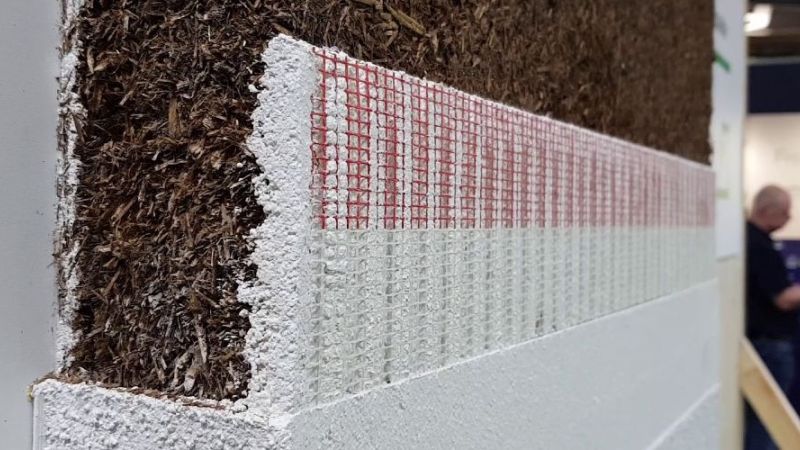

Mannheim power plant site

Grosskraftwerk Mannheim AG (GKM) operates several power plant units and one district heating storage system for MVV Energie AG at its site by the Rhine, flexibly and reliably supplying its customers with electricity, CHP heat, and steam in accordance with their requirements. Within the scope of the living lab, a large river water source heat pump with approx. 20 MWth will be built and integrated into a complex district heating system. Using efficient water abstraction systems that are already available, the pump will utilize the Rhine as a heat source to produce heat for one of the largest district heating networks in Germany. Three steam generators in the power plant are connected to each other via a steam busbar and can thus flexibly supply all downstream condensing turbines, traction current turbines and backpressure heating turbines with steam according to demand.

- Generation fleet before project start: 4 CHP power units

- Electrical capacity before project start: 1,958 MW

- Thermal capacity before project start: 1,500 MW

- Energy source used before project start: hard coal

- Planned thermal output of the large heat pump: 20 MW

- Heat source: Rhine water / cooling water

- Special features: Short pipeline routes, very good infrastructure available at the site, 43,000 m³ district heating storage tank

© GKM AG

© GKM AG

Rosenheim power plant site

The operation of several LHPs in a single CHP plant within the framework of three innovative CHP (iCHP) systems is planned at this site. Home to the centralized power plant system of public utilities company Stadtwerke Rosenheim, it consists of one waste-fired boiler, two gas-fired high-pressure steam boilers, two steam turbines, one reserve and peaking power plant, and seven CHP units. It uses waste, natural gas, biomethane, and wood gas as fuels, and has an output of 33 MWel and 115 MWth.

- Generation fleet before project start: Waste boilers, steam turbines, heating plants, CHP power units.

- Electrical capacity before project start: 33 MW

- Thermal capacity before project start: 115 MW

- Energy sources used before project start: waste, natural gas, biomethane, wood gas

- Planned thermal capacity of the large-scale heat pump: 1.5 MW

- Heat source: stream water

- Special features: 2 further GWP already planned within the framework of iKWK

© MHKW | Stadtwerke Rosenheim

© MHKW | Stadtwerke Rosenheim

Berlin power plant site

When the project launches, this site will be composed of two heating plants and one CHP unit (electrical output: 0.8 MW; thermal output: 28.7 MW). It will use natural gas as a fuel. Solar thermal power will be used as a basis for the LHPs project at this site. To provide the inlet temperatures required for district heating, the rise in temperature that is particularly required in transitional periods of the year will be achieved by a large-scale heat pump (1.12 MWth). The heat pump will be partially supplied with electricity from a photovoltaics system that will be installed at the site. As a result, it will demonstrate that a combination of different heat sources with a large heat pump is possible and can bring higher savings than the use of a single heat source. In addition, the possibility of increasing the daily and annual utilisation rate of solar thermal energy through the use of the large-scale heat pump will be explored.

- 2 gas turbines, 3 hot water generators, 1 CHP power unit

- Electrical output before project start: 10.6 MW

- Thermal capacity before project start: 50 M

- Energy sources used: natural gas and biomethane

- Planned thermal output of the large-scale heat pump: 1.2 MW

- Heat sources: Solar thermal energy, waste heat from gas turbines and CHP power units, geothermal energy, air heat

- Special features: Combination of PV, solar thermal, heat pump and district heating

© Vattenfall Wärme Berlin AG

© Vattenfall Wärme Berlin AG

Large-scale heat pumps contribute to sector coupling

The installed systems have the potential to feed renewable electricity into new and existing district heating systems with high efficiency. In comparison to electric boilers, they consume considerably less electricity for each thermal unit produced. In cooperation with district heat storage systems, they can allow for a temporary decoupling of electricity generation and electricity demand and thus contribute to the stabilization of the power grid. They therefore make a significant contribution to sector coupling and flexibilization in the electricity sector within the scope of the energy transition.

Larger units already in operation in Scandinavia

In the LHP living lab, large-scale heat pumps with a magnitude of up to 22 MWth per project are planned. Larger units with a combined system output of up to 180 MWth are already in operation in Scandinavia. A total of 420 MW in heat from LHPs is currently being fed into Stockholm’s district heating system.

“However, these units should primarily serve as inspiration and not be viewed as models to be emulated, since the German regulatory framework differs significantly from that of Scandinavia and their district heating networks are set up differently due to historical reasons,” explains Dr. Andrej Jentsch, head of the LHP regulatory sandbox project. He adds: “It can be helpful to look at Scandinavia, however, to identify promising solutions and to use these as a foundation for further developing large-scale heat pumps in Germany.” (bs/kka)