© ZSW

© ZSW

Photovoltaics

Environmentally friendly and efficient: thin-film solar cells in tandem

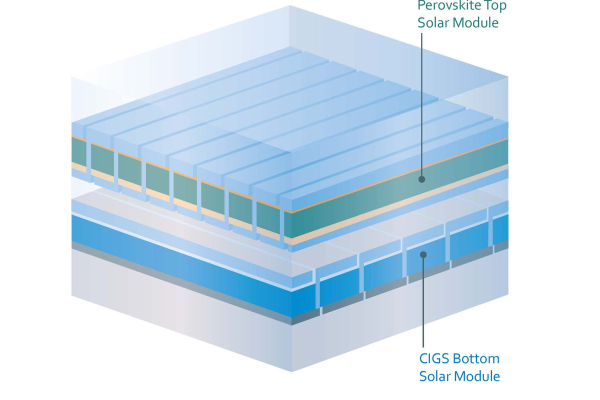

In order to further optimise solar cells and modules and achieve higher efficiencies, scientists are increasingly researching highly efficient tandem solar cells. These are composed of different types of solar cells. In the CAPITANO project, researchers have developed a tandem solar cell in which two thin-film-based solar cell types are combined: perovskite and CIGS solar cells.

The main motivation of the researchers at the Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and the Karlsruhe Institute of Technology (KIT) is to investigate concepts for pure thin-film modules based on perovskites and CIGS more closely and develop them further as in terms of the efficiency of the individual technologies science is getting ever closer to the physical performance limit. In the combined tandem form, perovskites and CIGS offer greater potential because they can make better use of the solar spectrum in this way. The upper cell is thereby made semi-transparent so that parts of the sunlight can penetrate to the lower cell.

Potentials of thin-film technology and further developments for tandem solar cells

Pure thin-film modules also offer additional advantages: Compared to other modules, they are lighter, cheaper and require less energy to produce. Due to their flexibility, they can be used in a wider range of applications and open up new fields of application. Furthermore, in contrast to silicon solar cells the band gap can be adjusted with CIGS solar cells. This in turn enables even better matching for tandem applications. In addition, thin-film modules ensure lower electricity production costs. Last but not least, these solar modules pay for themselves more quickly.

Overall, thin-film modules can perform better than silicon modules even in terms of sustainability. Silicon modules generally require more energy and more valuable resources (such as silver) in production.

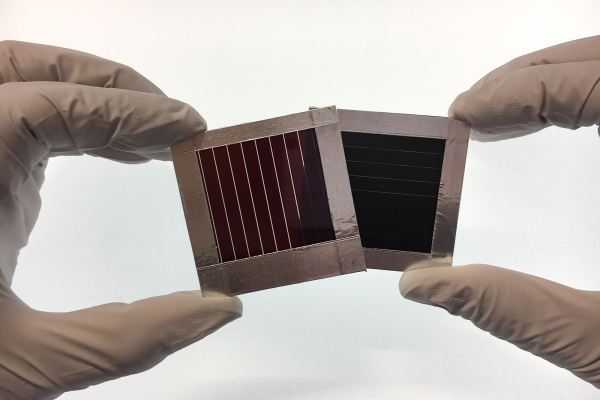

In CAPITANO, the research team first improved the individual cells used: CIGS solar cell and solar module as well as perovskite solar cell and solar module. In combination as a perovskite-CIGS tandem solar cell, the researchers finally achieved an efficiency of 27 percent, and as a perovskite-CIGS tandem mini-module an efficiency of 21 percent.

Perovskite solar cells produced with environmentally friendly solvent

Compared to other types of solar cells, it is easier and cheaper to produce perovskite solar cells. However, their production from ink solutions usually involves the use of environmentally harmful solvents. The raw materials of the perovskites must first be dissolved in these solvents for the coating. Only afterwards are they evenly applied to a carrier surface.

With its results, the CAPITANO research team shows that it is possible to completely avoid the use of toxic solvents - such as the most commonly used dimethylformamide (DMF). This is not only positive for the environment, but also has advantages for future production processes under industrial conditions. This is because perovskite solar cells must be able to be coated over large areas, which requires processes with solvents that are as uncritical as possible in terms of occupational safety and environmental protection.

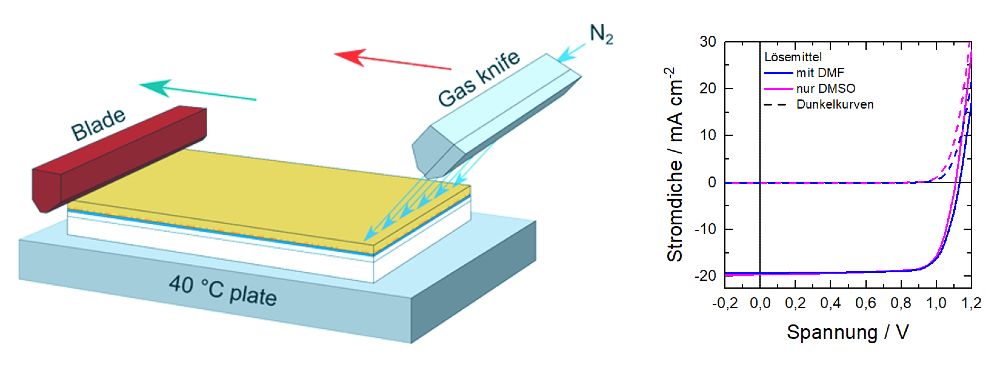

DMF is the most harmful solvent to health and the environment compared to other solvents typically used for ink deposition. Dimethyl sulphoxide (DMSO), on the other hand, is the most environmentally friendly alternative. The researchers have therefore developed a coating process for perovskites that uses only DMSO.

New coating process as a preliminary stage for industrial production

In order to transfer production to an industrial scale, the successful use of an environmentally friendly solvent is an essential step forward. Toxic solvents are associated with higher costs in terms of the waste produced, disposal and the necessary occupational health and safety measures. The researchers investigated the use of DMSO in the so-called blade coating process.

Due to its high surface tension and high boiling temperature, DMSO is basically not predestined for the coating process. These properties lead to the solar cell being coated unevenly. The researchers also had to take into account that the crystallisation of the cell can merely be insufficiently controlled with this solvent. Often, only small perovskite crystals are formed, which in turn leads to the cell being able to generate less solar energy.

Scientists were able to solve these problems with an optimised squeegee and drying process. The produced perovskite solar cell achieved an efficiency of almost 17 percent, almost the same as solar cells produced with DMF.

Coating technology on the way to industrial application

With the progress achieved, DMSO stands out as an environmentally compatible and industrially suitable solvent for the production of perovskite solar cells. The perovskite solar cells which were produced so far under laboratory conditions using the blade coating process are thus an important step towards industrial production. The process is scalable and suitable for production on an industrial scale, so that it can be used to manufacture large-area modules in the future.

Overall, the researchers in the CAPITANO research network for CIGS perovskite tandem solar cells have investigated various elements, including the individual cells, improved TCO layers (abbreviation for Transparent Conducting Oxides), semi-transparent top cells, tandem adaptation and module technology. Thus, the collaborative partners have optimised developments on architecture, perovskite composition and coating technology. The perovskite CIGS technology offers great potential for stable and cost-effective thin-film modules, so that the knowledge gained so far will serve the scientists for their further research on tandem modules and improved manufacturing processes. This will advance the still necessary further development of the modules to industrial application.

The challenges on this path are, in particular, to scale up the coating processes to the square metre scale. Long-term stability is also an issue. Which coating technology provides the best conditions for large-scale implementation cannot yet be conclusively assessed from a scientific and industrial perspective. In addition to the basic classification into solution- or vacuum-based processes, there are various sub-variants and hybrid approaches. However, with regard to high production speeds - both for coatings on rigid substrates and on flexible films in the roll-to-roll process - the researchers consider the slit casting process to be one of the most cost-effective variants. They are therefore continuing their research work on the further development of perovskite-based thin-film photovoltaics. (av)