© www.siemens.com/presse

© www.siemens.com/presse

Thermal power plants

Turbomachines indispensable even in a climate-neutral world

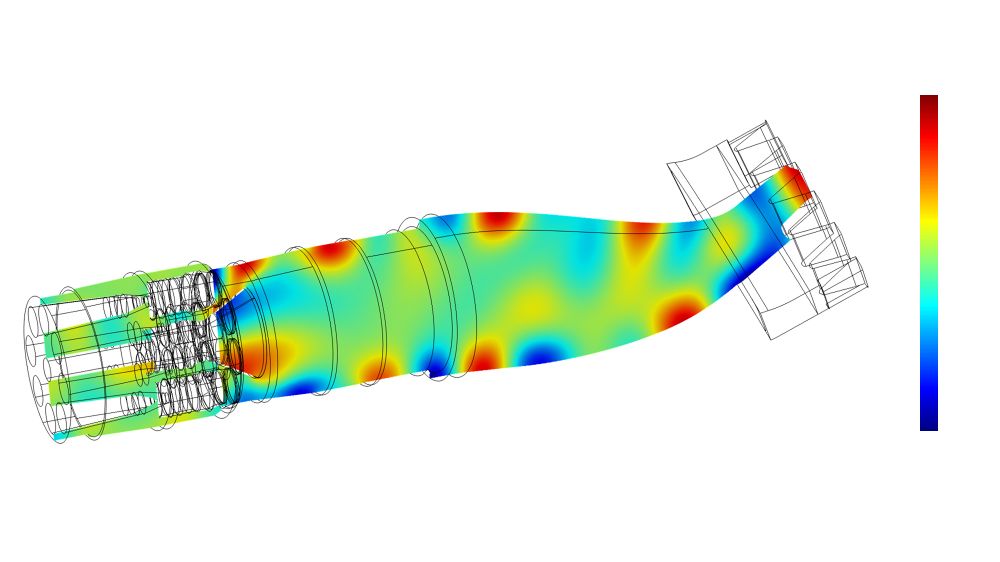

Away from fossil fuels towards liquid gas, biogas or synthetic gases such as hydrogen: In times of the energy transition, thermal power plants should partly or primarily use these fuels or fuel mixtures to operate efficiently and with low emissions. The power plants must furthermore produce power quickly, reliably and efficiently when the sun is not shining or the wind is not blowing. This poses major challenges for gas turbines. The joint ECOFlexTurbo project provides support here by researching combustion systems and developing them further for the next generation of gas turbines.

Flexible operation of efficient turbomachines

The steady expansion of renewable energy sources requires gas-fired power plants to be increasingly flexible in terms of operation and fuel. Especially frequent starts and transitions to partial load operation as well as operation with mixtures of natural gas and hydrogen up to pure hydrogen place a strain on the lifetime of the turbines and their components. Additionally, storage capacities integrated into the power plant process are needed for longer phases with insufficient electricity from wind power or photovoltaics. Here, green hydrogen, which is to be produced by electrolysis at times of surplus electricity from renewable energy sources and temporarily stored in power-to-gas plants for later reconversion into electricity, plays an important role.

This is why the ECOFLEX-Turbo research project focuses on increasing flexibility, efficiency and lifetime for new and existing plants. The components and technologies used must become even more robust in order to achieve the best possible efficiency with a long lifetime and low emissions at the same time.

One aspect of this is to monitor the plants accurately. For example, via regular recordings of the actual condition of individual components in order to determine the remaining lifetime and maintenance intervals. Project teams are for instance developing digital twins to monitor operations in advance (condition bases monitoring) and to be able to evaluate deviating operating states online. This is partly supported by digital methods, such as artificial intelligence and machine learning processes.

Making combustion systems fit for higher efficiency and flexible fuels

The development targets for higher efficiencies and fuel flexibility result in partly conflicting requirements for combustion systems. For example, turbine efficiency can be increased via a higher turbine inlet temperature. However, this increases the formation of toxic nitrogen oxides, which are harmful to health and contribute to acid rain, smog and global warming. This is why threshold limit values apply worldwide for external air as well as for exhaust gases from transport and power plants, which absolutely must be complied with. Measures to optimise efficiency with low nitrogen oxide emissions can conversely have a negative effect on combustion stability and lead to thermoacoustic oscillations. This reduces the lifetime of all gas turbine components. Similarly, the use of flexible fuels means that the efficient and low-pollution combustion systems no longer have to be optimised for a single fuel, but for a wider operating range. This can also increase emissions and/or destabilise the combustion process.

Teams of scientists in the ECOFlex-Turbo joint project are therefore working on combustion systems for the next generation of gas turbines in order to find a Pareto optimum of the competing requirements. This is a condition in which the parameters of the turbines are optimally designed for the use of flexible fuels with a variable proportion of hydrogen, for example.

Understanding and controlling thermoacoustic oscillations

The continuous combustion process generates flow noise, which is coupled to the flame via fluctuations in air pressure. This behaviour can lead to unstable combustion - the flame oscillates - also called thermoacoustics. Fluctuations occur in all frequency ranges. If these reach high amplitudes, for example because they amplify themselves or couple with natural modes of the combustion chamber or other components, components can be damaged prematurely, resulting in costly damage. Using flexible fuels can trigger thermoacoustic problems because, for instance, the flame position and flame length change depending on the hydrogen content.

This is where the ECOFLEX-Turbo project comes in. Project teams from industry (MAN Energy Solutions, MTU Aero Engines, Siemens Energy and Rolls Royce Germany) and research institutions (Technical University of Munich, German Aerospace Center) investigated various aspects to generate a more detailed understanding of the underlying processes between different, changing combustion conditions and different burner designs. This includes, for example, the influence of shorter exposure times of the combustion products in the combustion chamber as well as the gradation of the fuel-air injection into the combustion chamber. That means: In the combustion chamber, the flames are located at different positions which can be controlled independently of each other in order to be able to react adequately to flexible fuels.

Evaluating thermoacoustic stability

In another work package, the scientists developed a method to calculate the damping of acoustic oscillations in combustion chambers. For this purpose, they operated a laboratory burner under high pressure for the first time and generated variable, fuel-stepped flames with different emission values and measured them without contact using a laser. The measurement results obtained serve as the basis for design tools to predict emissions and oscillations and thus improve the combustion chambers.

Furthermore, the teams of scientists have developed methods to evaluate the thermoacoustic stability of burners. These should help to design future combustion chambers for different conditions. To do this, they researched the chambers with regard to their damping properties and then successfully tested the new methods.

The results obtained contribute significantly to understanding the influence of gases with admixed hydrogen on the thermoacoustics of modern gas turbine combustion systems. Based on this, the teams of scientists have already started further sub-projects by the Turbo working group with a focus on "hydrogen", the results of which are expected at the end of 2023. (mm)