© DLR (CC-BY 3.0)

© DLR (CC-BY 3.0)

Solar thermal power plants

Liquid salt stores heat

Molten salts can be used for the unpressurised storage of large quantities of heat at high temperature. Researchers from the German Aerospace Center (DLR) are using the new TESIS test system in Cologne-Porz to investigate where storage systems with only one tank can replace the previously common two-storage technology. The storage technology can save considerable costs.

Project context

Salt storage is a proven technology for solar thermal power plants. They make sure that the lights do not go out at night. The large thermal storage tanks can also support conventional power plants to respond more flexibly to load changes. This is becoming increasingly important so that the fluctuating infeed of renewable energy generation can be balanced out. Similarly, industrial processes often require high-temperature storage for large heat volumes.

Conventional systems work with two large heat-insulated steel tanks. When energy is required, the molten salt from the hotter tank is used and then pumped into the colder one. If there is excess energy, molten salt from the cold storage tank is heated and channelled back into the hot tank. The advantage of this concept is the simple system structure. The storage capacity is provided in large unpressurised tanks. The storage capacity is released and absorbed user-specifically in external components such as heat exchangers. The storage tanks release the heat to the process at a constant temperature level. The disadvantage, however, is the high cost of two separate tanks, which increases the costs.

Research focus

The focus is on the construction of a salt storage test facility, the only one of its kind in Germany, which is suitable as a platform for investigating storage concepts and liquid salt components up to 560 degrees Celsius. The size of the plant is dimensioned to allow tests to be carried out under realistic operating conditions. The experimental plan includes detailed investigations on heat and mass transfer, thermodynamics and material compatibility. In addition, the research teams optimise and qualify individual components and clarify process engineering issues.

TESIS:STORE – Heat stratification similar to that of hot water storage systems

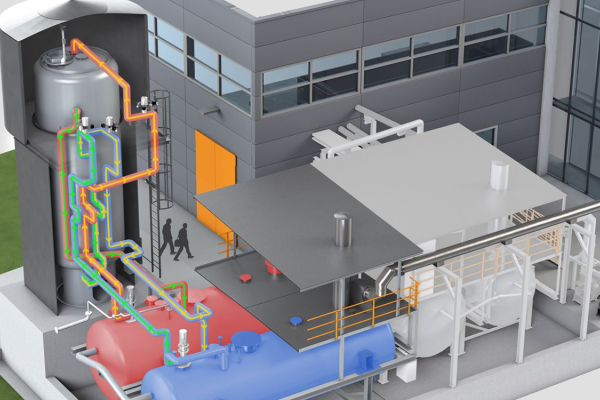

The test system on the DLR site in Cologne already looks different from the flat cylindrical tank twins (flat-bottom tanks) of solar power plants in southern climates. A single slender tower rises from the test facility. This houses the test storage system – called TESIS:STORE. The scientists intend to use it to scientifically analyse the single-tank storage concept and demonstrate its technological feasibility. Construction of the test system commenced at the beginning of July 2016 and the system was ready for operation in September 2017.

The plant component is currently operated with approximately 85 tonnes of salt. But the aim is to avoid filling the 20 cubic metre experimental storage tank completely with the comparatively expensive salt. Basalt stones as filling material reduce the required amount of salt. They have approximately the same volumetric thermal capacity as liquid salt. In this way the scientists combine the advantage of the pumpable liquid with the low price of natural stones.

Stable temperature strata play a decisive role in the salt reservoir. The thermal stratification of the salts in the temperature range between 170 and 560 degrees Celsius is still little researched and thermal stresses must be safely controlled. The hot salts have a corrosive effect on the components in the system. Freezing processes can block pipelines. The scientists intend to address these issues with detailed investigations of heat and mass transport, thermomechanics and material compatibility. The size of the test storage tank allows for scaling, model validation and system integration of innovative liquid salt storage tanks. Compared to systems available on the market, the single-storage concept has the potential to significantly reduce capital costs. The scientists believe that the cost reduction potential is in the double-digit percentage range.

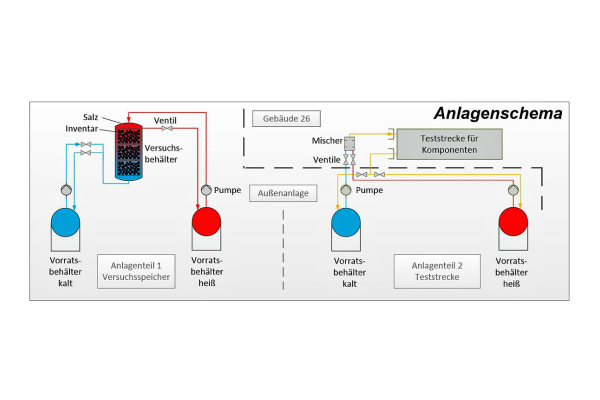

© DLR (CC-BY 3.0) | Illustration of the TESIS test system with vertical single-tank stratified storage facility with filling materials and four containers with a total salt mass of 115 tonnes. The horizontal tanks are used to shuttle the salt in research operations and are not required for the target application.

Test track TESIS:COM

In addition to the TESIS:STORE storage facility, the scientists built the TESIS:COM test track. Here, components such as valves, absorber pipes or measurement technology can be investigated and qualified. Process engineering questions for liquid salt, for example freezing processes, are also to be answered here. DLR also intends to offer this service to external clients.