© DBFZ Deutsches Biomasseforschungszentrum

© DBFZ Deutsches Biomasseforschungszentrum

Bioenergy

Flexible electricity production from biogas

Compensating supply fluctuations will prove vital in future electricity grids utilising high proportions of wind and solar power. A demand-led generation of electricity from biogas can contribute to this. Researchers are developing new systems and software for biogas plants that enable flexible operation. These precisely monitor and control the biogas production and electricity generation. The aim is to precisely coordinate these processes and make optimum use of storage capacities.

Project context

The flexible generation of electricity from biogas is an important component in the future energy supply for balancing intermittent energy sources. At the biogas plant site, it is possible to decouple the gas production and conversion using appropriate storage capacities and controlling the biogas production. Integrated gas management, which makes the best possible use of the existing storage capacity, can make a considerable contribution to improving system services and avoiding emissions and flare losses.

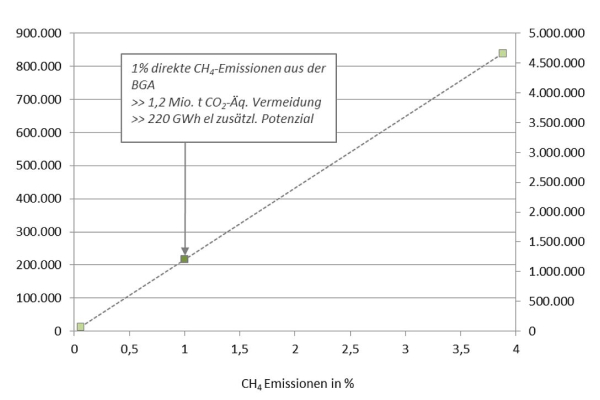

The planned project is to technically improve gas storage systems – in particular the storage level measurement – and integrate them into the process control system for biogas plants in order to upgrade them for growing energy requirement profiles. The further developed systems can also be implemented in the future at a large number of existing biogas plants with different gas storage systems and thus also contribute to significantly reducing operational emissions.

Minimising gas losses

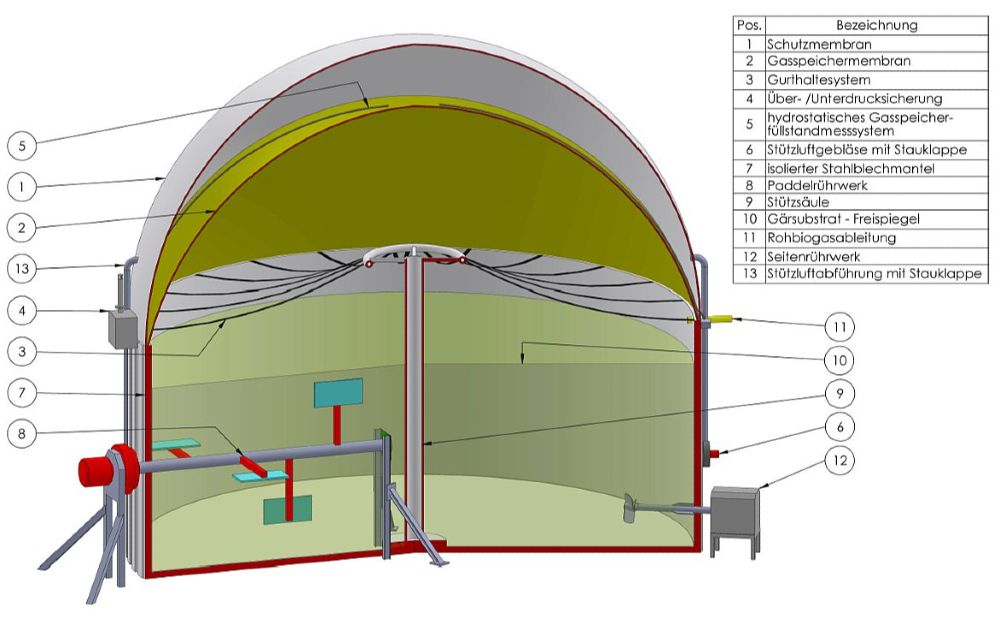

Biogas plants in Germany primarily utilise double-membrane gas holders. According to the 2016 DBFZ operator survey, these account for around 62 per cent of the overall number of holders. These gas holders with an integrated design sit directly on the digester. The researchers focussed their investigations on these widely used storage systems, which also offer favourable properties in combined usage.

If there are unsuitable internal pressure conditions when operating several gas holders in combination, the net gas storage capacity is not fully utilised and the gas holders are not sufficiently filled. It is therefore advisable to take appropriate measures to adjust the internal gas storage pressure, for example by means of adjustable support air blowers.

For operation, the shortest possible pipes with the largest possible cross-section and few bends offer ideal conditions. If several gas holders are to be filled and the pipe periphery experiences high pressure losses, it may be necessary to interpose a gas compressor.

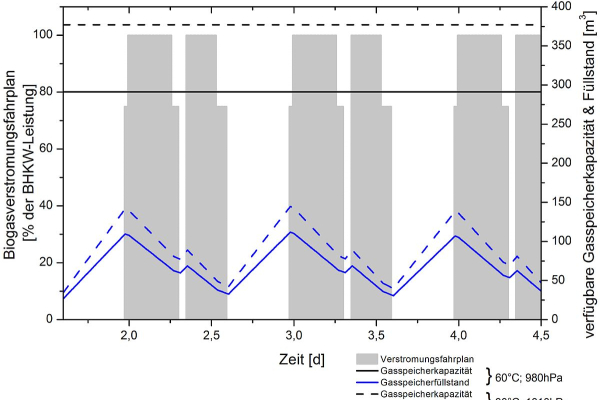

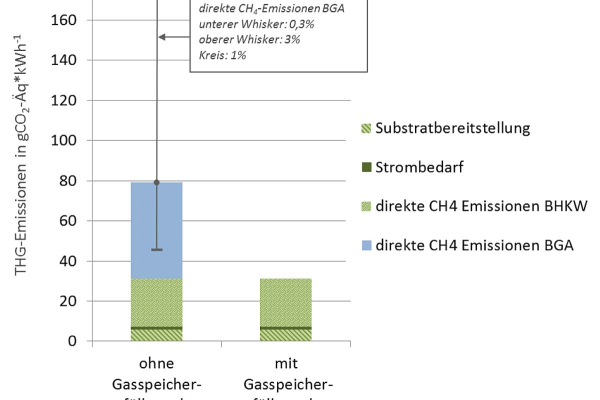

The aim of gas management is to prevent biogas losses and emissions and to render usable as much storage volume as possible as a buffer between the gas production and utilisation. Biogas losses resulting from protecting gas holders against over-/under-pressure can be avoided without additional components by simply adjusting the operation. During normal operation the gas holder should be operated at a filling level of around 50 per cent and, for example, not be technically full before sunrise. The available storage capacity is optimised through technical improvements to the plant, for example by integrating support air blowers that are frequency-controlled using measurement technology. Further refinement is achieved by using a model that enables the filling level of the gas holder to be precisely forecast and thus predictively regulated.

Research focus

In the "ManBio" research project, research teams worked on technically improving systems for measuring the filling level of gas holders. The researchers integrated these in the process control system for the biogas plant. As an initial step they collected extensive data on the technical status of gas holder and filling level measurement systems. The researchers also recorded process data such as gas production rates, gas consumption, temperature and air pressure. They used this data to better predict the behaviour of the gas production process chain as well as gas holder capacities, gas holder filling levels and consumption rates.

Based on this the researchers developed a gas holder model and, derived from this, a model for forecasting the filling levels under different weather conditions. The model can use current weather data and gas holder internal temperatures. To measure the level even more accurately, they modified a rope length method and used two hydrostatic pressure measurement methods in parallel. The researchers tested this process on a research biogas plant belonging to the German Biomass Research Centre and a further biogas plant maintained by the practice partner.

© DBFZ Deutsches Biomasseforschungszentrum | Gas holder filling level measuring systems significantly reduce total greenhouse gas emissions. If the methane emissions resulting from over-/under-pressure protection and leaks are prevented, the emissions from biogas plants drop to just under 35 grams of CO2 equivalent per kilowatt of electricity.

Results

The research teams identified potential errors and showed how to avoid them. They developed recommendations for practical plant operation. The researchers summarised the most important aspects in three specific recommendations:

- The procedure for accurately measuring the filling level must be suitable for the respective storage type. In the case of pneumatically pre-stressed, double membrane gas holders with support air blowers and air vanes, a suitable method is to record the shape of the gas holder’s internal membrane using rope length or hydrostatic pressure measuring with a water level. As the internal pressure in these gas holders remains constant above the entire filling level range, the method occasionally used in practice of measuring the internal pressure of the gas holder is not suitable.

- The gas storage system must be able to compensate for unavoidable filling level fluctuations during normal operation, which are caused, for example, by weather events, feeding fluctuations or the failure of components such as the CHP unit. Over- and under-pressure events must be avoided. This can be achieved by the filling level-controlled operation of a secondary gas load, such as an emergency flare stack. If over-pressure events occur, the cause must be ascertained and eliminated in order to stop unwanted emissions.

- The demand-led provision of raw biogas increases the requirements on storage systems: the storage volume should be fully available. To ensure optimal use of the net gas storage capacity, a controllable exchange of raw biogas between the gas holders and the conversion units must be ensured when several holders are interlinked. Control is facilitated by measuring and actively configuring all internal pressures within the integrated gas holders, for example using adjustable support air blowers.

Forecasting models for flexible operation

A Fuzzy Logic Expert System developed by the Awite project partner now also covers the gas and CHP management.

The researchers are planning to expand this system to provide overall plant control. The forecasting model uses current weather data from the German Weather Service. This will also enable more flexible feeding; the system then reduces the substrate input, for example at higher temperatures.

Mathias Stur, project manager at the German Biomass Research Centre, was conferred the German agricultural industry’s Biogas Innovation Award in 2017 for the research work on improving gas management in biogas plants.