© MAN Energy Solutions SE

© MAN Energy Solutions SE

Thermal power plants

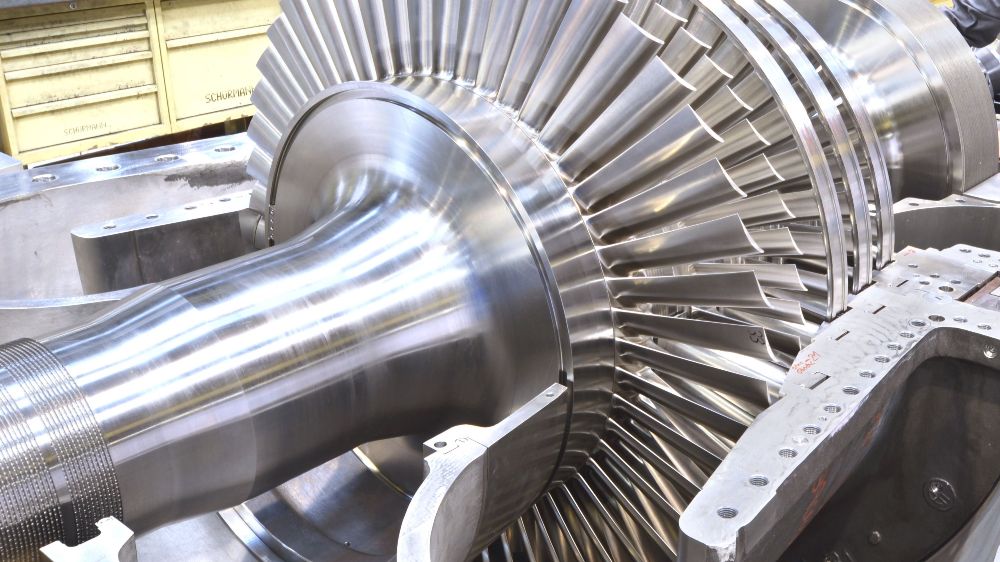

Turbomachinery for green fuels and energy storage

In the TurboGrün research project, teams of scientists are working on efficient gas turbines and turbomachinery powered by hydrogen or natural gas-hydrogen mixtures. These are being further developed for use in mechanical and thermal storage systems.

Thermal power plants are also in demand in times of the energy transition. The plants must produce power quickly, reliably and efficiently when the sun is not shining or the wind is not blowing. It is therefore necessary to adapt operating processes and components. Additionally, further storage capacities integrated into the power plant process are required. These should store surplus power in the form of hydrogen, heat and mechanical energy and convert it back into power when needed. One focus of the research work is to optimise turbomachinery for energy-intensive industrial processes, for example for the chemical industry. Scientists from industry and university research institutions are investigating these and other aspects in the TurboGrün project, short for "Turbo Machines for Energy Storage and Green Fuels".

Efficient gas turbines use hydrogen

Surplus power from renewable energies can be used to produce so-called green hydrogen by electrolysis. In this process, water is broken down into the components hydrogen and oxygen. In the work package "Stable, flexible combustion of climate-friendly fuels", TurboGrün researchers focus on the task of efficiently using hydrogen in pure form or as a natural gas-hydrogen mixture with turbomachinery. For this process, they develop robust burners and optimise sealing and cooling concepts.

Another aim of the teams of scientists is to improve the manufacturing technologies of gas turbines and turbomachinery. This allows the efficiency of the plants to be increased. They are therefore planning to develop so-called digital twins in order, for example, to predict the lifetime of individual components more accurately and to optimise maintenance intervals.

Charging and discharging storage systems with turbomachinery

In future, energy storage systems are to be integrated into the power supply system in conjunction with renewable energy sources. Turbomachinery is essential for this. It can be used as expanders and compressors. This gives it the potential to charge and discharge storage systems cost-effectively, flexibly and with high efficiency. However, this creates new requirements for densification and expansion units. That is why researchers are investigating turbine technology in the "TurboGrün" project. Expanders, for example, have to withstand high temperatures so that they can use the stored heat to generate power again. In addition, the systems require secure seals to prevent process gases from flowing into the environment. To complement this, the future centrifugal compressors are to be planned and built with the help of new design methods. The aim is to use these efficiently in mechanical and thermal storage systems. (mm)