Bioenergy

New solid biogas plant: decentralised and cost-effective

Following a successful planning application, the construction of a residue biogas plant started on 30 September in Kirkel-Altstadt in Saarland with a ground-breaking ceremony. Approximately 2,500 tonnes of solid substrates such as horse manure or cuttings from landscape maintenance are to be fermented here every year. Researchers accompany planning, construction and operation over several years. The aim is to make a new type of biogas plant fit for the commercial market.

Biogas plants usually use liquid substrates whose dry matter is less than 15 per cent. However, solid residues, such as manure with a high straw content, cuttings from landscape maintenance or crop residues from cereals (dry matter greater than 30 per cent) are also to be used in future. These substances cannot be used in the usual wet fermentation without complex methods. Moreover, these residual materials only occur locally in small quantities and result in high transport costs. This means that their share in the total biogas production is quite small.

In rural areas, small plants with an electrical output of up to 75 kilowatts offer a technically sensible solution. However, these plants are primarily designed for liquid manure. The more suitable alternative from a technical point of view is solid matter fermentation (dry matter greater than 20 per cent). At present, this method has electricity generation costs of more than 20 cents/kilowatt-hour electric for smaller biogas plants. This means that economic operation is not possible. This is where the FeBio project comes in, short for “Putting residues to good use in a targeted way - development of a new low-cost solid biogas plant”.

Testing and optimising new solid biogas plant

The scientists’ goal is to develop, test and optimise a pilot and demonstration plant for the dry fermentation of solid raw materials. The investment costs should be below 8,000 euros/kilowatt electric, so that even small biogas plants can be assured of electricity generation costs of around 18 cents/kilowatt-hour electric.

Simple and smart is the motto

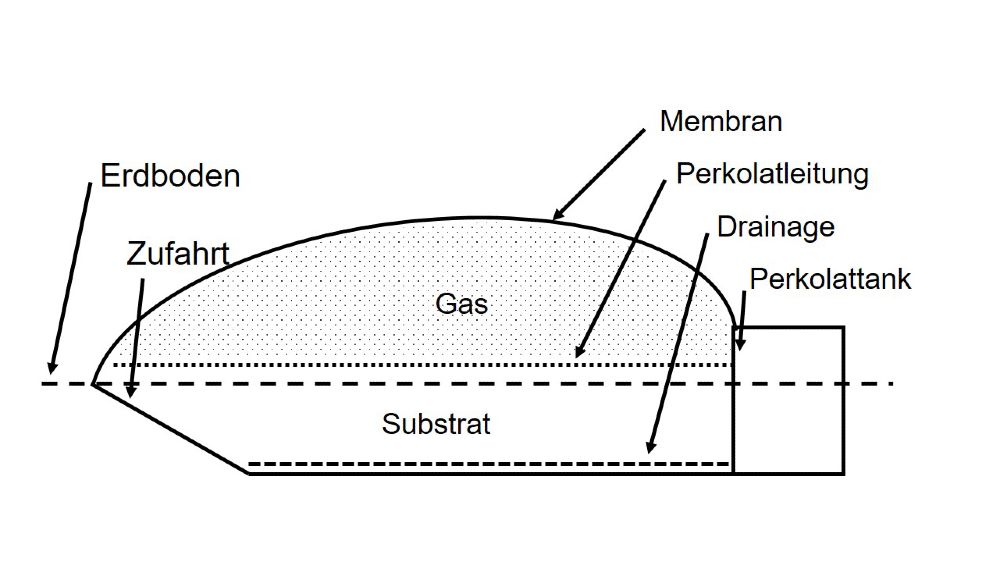

The technical design of the FeBio plant should be kept simple. This also allows the owners to carry out work themselves and save costs.

Part of the plant will be constructed as a container housing all the technical elements, such as the CHP plant with 75 kilowatts of electrical output and control system. Another advantage: The digester bottom is below the surface line. This makes the digesters easier to load and unload, and liquids produced during fermentation cannot spontaneously spill out. Heat and water for the fermentation process are provided in a closed recirculation system. The system utilises the exhaust heat from the CHP plant and the water released from the substrate and collected in the buffer tank for this purpose. Finally, a process control system monitors the most important parameters.