© DLR (CC-BY 3.0)

© DLR (CC-BY 3.0)

Solar thermal power plants

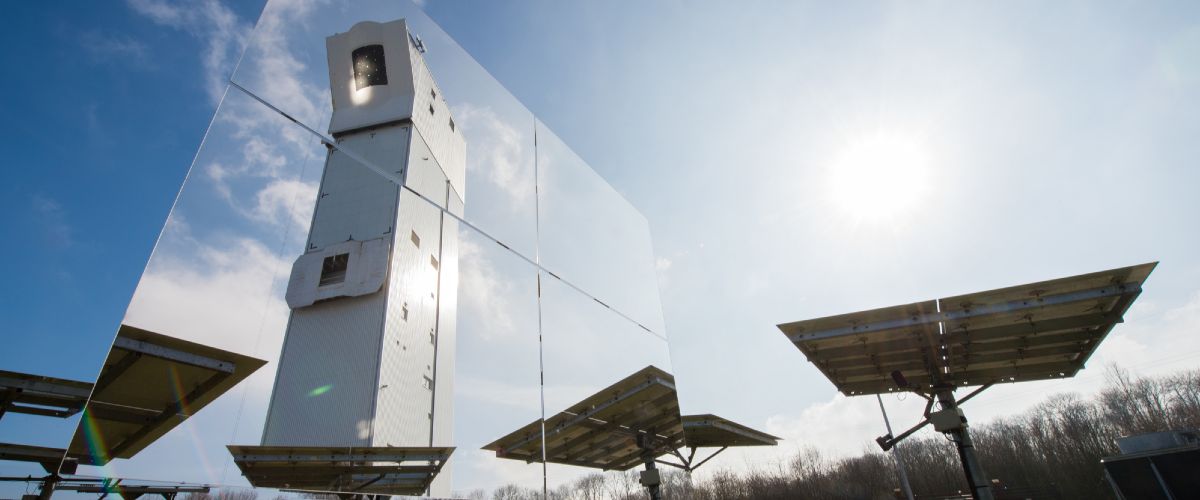

10 years of research at Solar Tower Jülich

In contrast to commercially operated solar thermal power plants, electricity production at the Jülich solar tower is not the central concern.

The Jülich solar tower was officially inaugurated in August 2009 and has been operated by the German Aerospace Centre (DLR) as an experimental power plant since 2011. A feature of the tower is that it is completely in the hands of a research institution: “This means that we have access to all components in the power plant – the heliostat array, receiver, power plant technology, heat storage unit and control systems,” explains Felix Göhring, who is responsible for the facility at DLR. This enables the researchers to be active at all points in the power plant where there is something to optimise. In contrast to commercial plants, a research platform halfway up the tower can be exclusively used for experiments.

To operate the power plant, the sunlight is bundled via the heliostats, which are mirrors that track the movement of the sun. The concentrated light is then projected onto the radiation receiver at the top of the tower. There it is converted into heat. The heat thus obtained is then used to generate steam in a boiler and drive a turbine. Finally, a generator is used to generate electricity. Excess heat can be transferred to a heat storage system. When there is less sunlight, for example when a cloud passes by, the stored heat can be fed back into the boiler. This enables the power plant to be operated without interruption.

Research focus on receiver technology

In recent years, research at the Jülich solar tower has focused, among other things, on improving the technology of the air receiver, which is also the subject of the current VORWAiRTS project. The scientists are hoping that this technology, which in contrast to receivers with steam and salt melts is not yet commercially in use, will provide high process temperatures and efficiencies.

In addition to further developing the air receiver, Jülich is also conducting research in many other areas. For example, a milestone was reached when a tested particle receiver achieved a temperature of 900 degrees. By way of comparison: In commercially operated power plants, which generally operate with salt melt receivers, temperatures of around 560 degrees are reached. In addition to improved efficiency, the high temperatures are also particularly important for solar process engineering, such as solar fuel generation.

Technology for export markets

The tower is also important for industry. The projects are therefore usually based on a specific interest of an industrial partner. "The tower is a kind of germ cell around which an entire site has developed," says Göhring. This can also be seen in numerous spin-offs from the institute, which have specialised, for example, in control systems, the marketing of individual components or measurement technology.

Due to the low annual solar radiation, the technology developed at the Jülich site will never be used commercially in Germany. "It only becomes really interesting south of the 35th parallel," explains Peter Schwarzbözl, who is working at DLR on the technology of the air receiver. For this reason commercial facilities are therefore situated in, for example, Morocco, China, the USA and Chile. Although the proportions supplied by German companies for solar thermal power plants abroad are already very high, the potential supply share could be almost 100 per cent. "This means that German technology could be used to build a complete power plant," says Schwarzbözl. The technologies developed in Jülich together with industry are therefore also potential export items.

Creating the conditions for more research

Those responsible at the site expect further exciting research topics in the future. In addition to the ongoing further development of individual components, such as the heliostat, and further research into the various receiver technologies, the scientists also hope to make progress in the production of green fuels, such as solar hydrogen for road traffic or solar kerosene for aviation. It is also intended that a largely automated solar power plant using intelligent control systems will be demonstrated at the Jülich site over the next few years.

In order to create the conditions for this, the site is currently being expanded to include a second tower, the so-called multifocus tower. This will comprise three additional test platforms but, unlike the old tower, will not contain any power plant technology for electricity generation. This will enable them to carry out significantly more scientific experiments – including in parallel, work more continuously in future and make even better use of the available solar radiation.

Storage for a stable energy supply

Those involved see an important role for solar thermal power plants in supplying sustainable energy in the future. A major advantage of this technology is its storage capacity. For example, a heat storage system can be charged during periods when more energy is available than is consumed. It can then be discharged again during periods when less energy is available. "This is technically very easy to implement and clearly distinguishes this technology from wind turbines and photovoltaics, which are now very inexpensive but fluctuate greatly with the supply of sun and wind," says Schwarzbözl. Plants like the one in Jülich have real turbine generators like steam power plants. They can therefore maintain the load in the grid in a targeted manner and thus offer the same grid services as, for example, coal-fired power plants.

In addition, the scientists believe that there will be many other applications for solar thermal systems in the future. In particular, the high temperatures generated mean they could play an important role in industrial processes, such as in process engineering for chemically converting specific substances, or for direct thermal use such as drying processes.